ISO 50001: Certified energy management system

There are many good reasons to pay attention to the energy efficiency of your organisation. From a global point of view, it helps with the urgently necessary reduction of greenhouse gas emissions. But an energy management system certified according to ISO 50001 also offers economic benefits.

A certified energy management system according to ISO 50001 can support you in the continuous improvement of your energy performance, i.e. in the improvement of energy efficiency, energy use and energy consumption. This leads to ongoing and sustainable reduction in your energy costs, which in turn increases your competitiveness. Your image towards the outside world is also enhanced.

Benefits of certification according to ISO 50001

-

Your company considers its energy performance systematically, and identifies and utilises energy saving potentials

-

You raise the awareness of your employees and suppliers for sustainable use of energy resources

-

You save costs through lower energy consumption

-

You support general climate protection goals through reduction of CO2 emissions and help to conserve resources

-

You present yourself to the outside world in a more positive way

-

Industrial production companies can make use of tax reliefs such as the tax cap (Spitzenausgleich) specified by the German Electricity Tax Act and the German Energy Act (§ 10 StromStG, § 55 EnergieStG) and the limitation of the energy surcharge (Umlagebegrenzung) as specified in the German Renewable Energy Sources Act (§ 64 EEG).

-

You are freed from the obligation to undertake energy audits according to DIN EN 16247-1

-

Eventually, your competitiveness increases

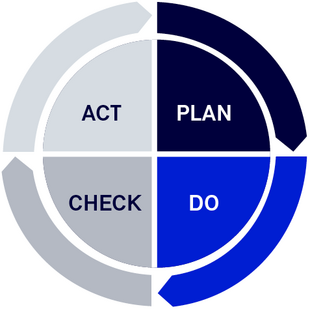

"Plan-Do-Check-Act" as the basis of your energy management system

ISO 50001 is based on the Plan-Do-Check-Act model. This is divided into four phases and can be understood as a continuous process of improvement. This continuous process of improvement is intended to prevent downtimes and ensure that organisations adapt to changing situations in good time and achieve new potential savings.

Plan: First there is an energy review: the energy starting position is determined, energy performance indicators (EnPIs) are laid down, energy objectives and policy are established and action plans are designed.

Do: In the Do phase, the energy management system (EnMS) is introduced and there are first steps towards implementation. Alongside creation of the necessary structures, this can mean establishment of communication and documentation processes and also training of employees. These must be able to demonstrate skills and competence on both the technical and the awareness level.

Check: In the Check phase, the emphasis is on monitoring, measurement and analysis of the energy performance. A management review takes place at the end of this phase, and actions are either terminated, modified or permanently implemented.

Act: In the Act phase, new actions are taken to continously improve the energy performance and the EnMS. It may also be necessary to make corrections, e.g. to the energy objectives, the EnPIs, the baselines or the energy policy.

The accreditation of TÜV NORD CERT GmbH (TN CERT)

was successfully transferred by the German Accreditation Body (DAkkS) to the international accreditation standard DIN ISO 50003:2022 on 02.08.2023.

The transition will result in changes regarding the calculation of the audit time as well as conducting the audit implementation and the audit documentation.

Your certificates and, if applicable, sub-certificates do not change due to the transition.

For existing customers, the new calculation requirements only apply to the next re-certification. The changes regarding conducting audit and audit documentation, on the other hand, apply immediately, i.e., they will be implemented in the next audit of the current certification cycle.

For new customers, all requirements according to DIN ISO 50003:2022 apply with immediate effect, i.e., the new calculation requirements and the changes regarding the conducting audit and audit documentation.

Main changes compared with the previous edition are as follows:

What has changed?

Changes for audit day calculations

- Weighted values for complexity (calculation)

- Pareto approach for determining energy types (customer questionnaire)

- Consideration of external energy using systems and sites without staff (customer questionnaire)

Audit planning and audit documentation

- Auditing of a sample of primary data sources (e.g., energy bills)

- Documented time slot for auditing primary data sources (audit plan)

- Documented energy consumption by energy source and location (audit report)

Audit duration

- A minimum of 80% of the calculated audit time shall be spent on site (previously 70%).

- A maximum of 20% of the calculated audit time shall be spent on audit preparation and follow-up.

Continual energy performance improvement

- During surveillance audits the audit team shall review measures taken by the organisation to improve the energy performance of the organisation. During the surveillance audits, demonstration of the achievement of energy performance improvement shall not be required.

- During re-certification audits the audit team shall determine based on energy performance indicators (EnPIs) whether continual energy performance improvement has been demonstrated by the organisation.

Multisite

- Several sites can be considered as a single site if they are near each other. Thus, the number of EnMS effective personnel, energy types, energy consumption and number of SEUs can be summarized.

Audit planning

- Audit plan requires specified time slots for checking the primary data sources (e.g. electricity bills)

Audit documentation

- Information about the organization

- Total energy consumption

- Breakdown of consumption by energy source and location

- Total number of personnel

- Number of EnMS-relevant personnel

- Distribution of consumption and employees across locations

Results from the inspection

- Plants

- Measuring devices

- Measuring systems

- Cross-shift auditing

- Results of site audits

- Well-founded statement on improvement of energy performance:

- In the case of surveillance audits, at least the implementation of measures to improve the energy-related performance must be verified.

- In the case of certification and re-certification audits, evidence must be provided that the energy-related performance has been improved.

FAQs

ISO 50001 is an internationally valid standard which specifies the requirements for an energy management system for an organisation or company. It is intended to support the establishment of a useful and systematic energy management system with the aim of achieving more efficient use of energy.

There is basically no obligation to undertake certification, and the establishment of an energy management system is voluntary However, in Germany certification according to ISO 50001 is the prerequisite for important tax reliefs, such as the tax cap or a limitation of the EEG energy surcharge.

According to §§ 8 ff. of the German Energy Services Act (EDL-G), all companies which are not SMEs in the sense of Commission Recommendation 2003/361/EC are obliged to undertake an energy audit at least every four years in accordance with DIN EN 16247-1.

Organisations which operate a certified energy management system according to ISO 50001 or which can demonstrate an EMAS III Validation are released from this obligation.

All “non-SMEs” are affected:

- companies with ≥ 250 employees or

- companies with an annual turnover of > 50 million € or

- companies with an annual balance sheet total > 43 million €

Please note that associated companies are also taken into consideration when categorising a company as an SME or non-SME. More detailed information on the definition of SMEs can be found in the European Commission Guideline.

Further information on how an energy management system can be developed and efficiency potentials identified and assessed based on an energy audit can be found in in the practical guide to energy management "Energy Management Systems in Practice" published by the German Environment Agency (UBA).

Industrial production companies use their energy management system as a basis for applying for the tax cap (§ 10 StromStG, § 55 EnergieStG) or a limitation of the EEG energy surcharge (§ 64 EEG).

As was already the case with ISO 9001 and ISO 14001, the High Level Structure was used as a basis for ISO 50001. This ensures standardised headings and numbering of the individual clauses and also standardised terms and definitions.

The organisation has to determine external and internal issues that can affect the energy management system either positively or negatively.

The organisation has to determine and specify the interested parties that will be relevant to their energy management system and also their relevant requirements and expectations.

Organisations have to address existing risks and opportunities in relation to their energy management system and plan their activities accordingly.

ISO 50001 emphasises the responsibility of the top management more strongly than before with regard to the development and operation of the energy management system.

The requirements as to methods used for monitoring, measurement and analysis of energy performance are more stringent.

The additional time required for transitioning to the new standard was laid down as follows by the German Accreditation Body (Deutsche Akkreditierungsstelle, DAkkS):

- During a recertification audit: +10 per cent, however at least 2 hours on site

- During a surveillance audit: +20 per cent, however at least 4 hours on site

On 14 October 2017, accreditation standard ISO 50003 became the new basis for certification of management systems according to ISO 50001. This also has an impact on organisations who are already certified according to ISO 50001 or who wish to achieve certification. Seen as a whole, there is now a greater focus on energy efficiency. Further information on ISO 50003 can be found here.

Certification with TÜV NORD

TÜV NORD is recognised as a well-established and reliable provider of inspection and certification services, assessing fulfilment of legal regulations and voluntary standards all over the world. We employ experienced specialists in all our areas of activity. As a matter of principle, aur auditors are trained to a very high level and use standardised methods. This means we can guarantee neutrality and continuity in all our services to you.