24 March 2022

In a development accelerated by the pandemic and made possible by digital technologies, ever larger numbers of tests can now be carried out remotely. This is saving both money and CO2 – because the experts from the TÜV NORD GROUP no longer necessarily have to fly around the world to do their jobs. Read on to discover how remote inspections can be used to inspect bridge cables in Taiwan or off the coast of Norway.

Used in situations ranging from bridges, cable cars and radio transmission masts to conveyor cages in mines, steel cables carry loads weighing many tons. If they are to remain in good condition in the long term, they must be checked regularly. The good news is that DMT’s experts will no longer necessarily need to fly around the world in the future to do this. This is because the TÜV NORD subsidiary has become the first company to offer remote-assisted cable tests. Remote inspection is the keyword here. The technique was first tested using augmented reality (AR) on a radio transmission mast belonging to a German TV station. It was then deployed in Taiwan for a bridge test. Another pair of AR glasses is currently being tested in Norway as part of a cable test on the high seas.

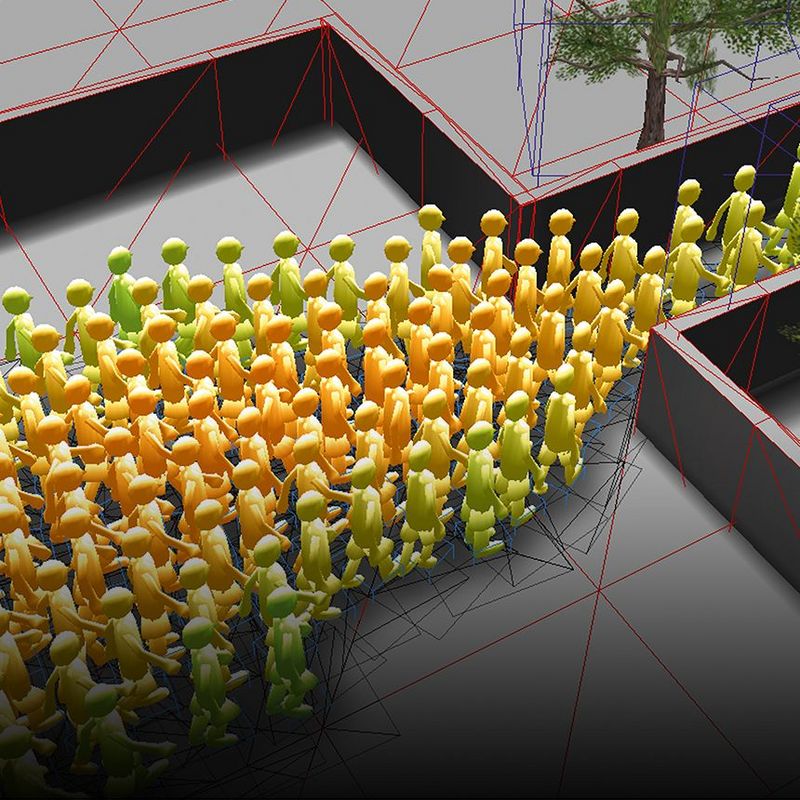

© DMTThanks to high-resolution images that are on site, a good interaction of inspectors on site is between inspectors on site and the DMT teams in Essen is possible.

In a magnetic-inductive cable test, cables are tested for internal and external wire breaks, deformations and corrosion, all without any need to remove or open them up. For this purpose, a special test magnet is installed around the cable, and sensors detect stray magnetic fields that indicate irregularities within it. The experts can then use the recorded data to draw conclusions about the cable’s safety. “As a rule, we do our inspections in pairs or threes with the support of the customer on site. This means an enormous amount of planning every time – who has time when, what will the weather be like, what equipment will we need, and so on,” says Dominik Bartsch, expert at DMT, by way of explanation of the current procedure.

Show, don’t tell

The remote cable tests will reduce the planning costs and labour to a minimum. Inspectors from local partner companies are trained in advance in the use of the equipment. During the actual inspection, communication between the DMT experts in Germany and the inspectors on site involves AR glasses and a platform on which the data are cached for further processing. The AR glasses transmit the images of the inspection work to Essen and enable the DMT team to use visual representations to explain movements or information to the inspectors on the ground. “This makes communication a whole lot easier, especially with international orders. Showing something visually is always clearer than describing it in words, especially in complex test conditions,” says Dominik Bartsch. This means that, in terms of safety standards, remote testing is in no way inferior to conventional methods. “If the measurement data show that further tests are required, we send our own experts to the site,” adds Bartsch.

Sending technology around the world instead of people

Where employees once used to travel around the world, in future it will only be equipment and AR glasses which will make the journey. The rest of the work will take place online under the most stringent data protection regulations. “In many cases, AR is really simplifying the work. This applies, for instance, to initial or repeat inspections of building sites in construction and dismantling projects, laboratory tests, work to determine the causes of fire and initial visual inspections after serious fires, and special firefighting,” explains Margareta Spajic, project manager in the Digital Business Development & Technologies department at DMT. “We’re benefiting from the fact that the AR glasses transmit high-resolution images and the data are quickly and readily available. I can also look at them on a smartphone,” says the remote inspection expert.