Hydrogen storage: from compressed gas storage to hydride storage

Various methods are available for storing hydrogen (H2). Pressurised storage and cryogenic liquid storage of hydrogen are the most commonly used in industry. Pressurised hydrogen storage can take place in steel tanks or tanks made of a composite material. These are used, for example, for lorry transport, vehicles and hydrogen storage in industry or at hydrogen filling stations. The pressure level here is between 20 and 90 Mpa. To store hydrogen in vehicles, the automotive industry relies on the use of pressurised tanks with a pressure level of up to 70 Mpa. This means that fuel cell vehicles have a similar range to petrol vehicles. It is also generally possible to store hydrogen in gasometers at extremely low overpressure (0.0022 bar).

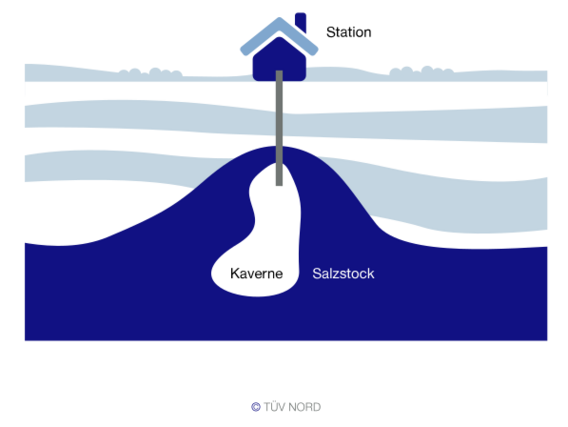

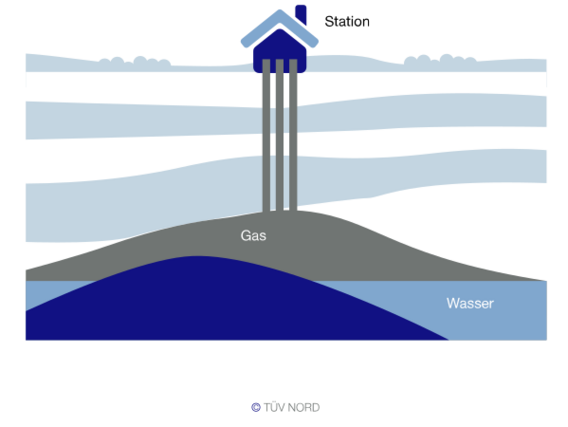

Storage in salt caverns is suitable for extremely large quantities of hydrogen. These have a geometric volume of 70,000 to 600,000 m³. Underground pore storage facilities also offer great potential as hydrogen storage facilities. Metal hydrides (chemical compounds of metals with hydrogen), on the other hand, are used to store smaller quantities of hydrogen. Other processes, including the storage of hydrogen in complex hydrides or the physisorption of hydrogen in porous materials, are currently still being researched or are only used in niche areas.