Against the backdrop of rising energy costs and demands from the German government to reduce CO2 emissions, energy saving and energy efficiency are becoming increasingly important. There is considerable potential to fulfil these requirements in the fields of refrigeration, air conditioning and ventilation technology as well as in building services engineering.

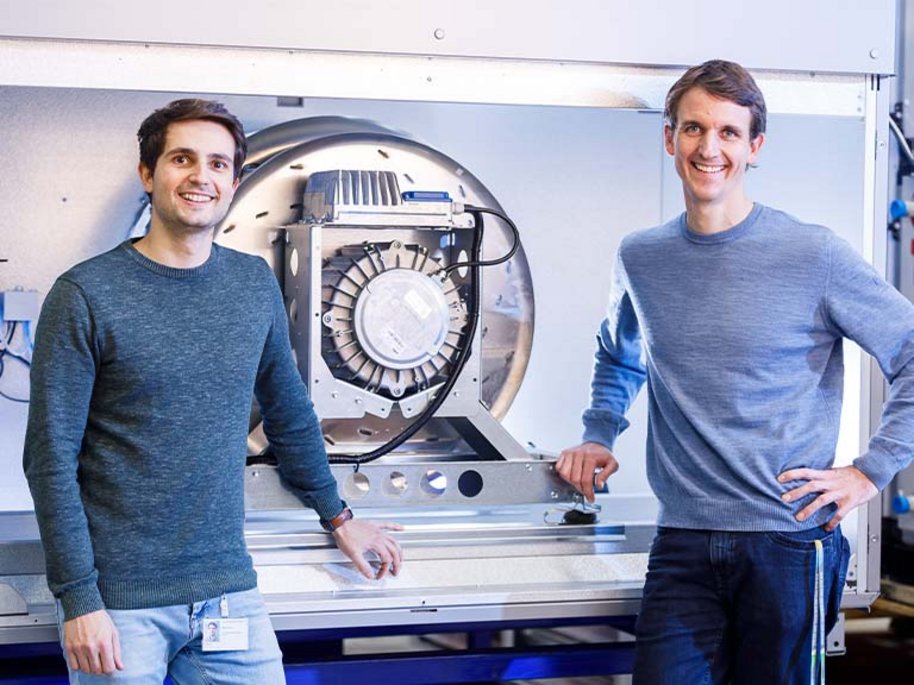

As a recognised and independent test laboratory, we offer a wide range of tests for refrigeration, air conditioning and ventilation equipment and systems based on national and international standards and guidelines. Our test laboratory is accredited in accordance with DIN EN ISO/IEC 17025 .

Thanks to our modern, versatile testing technology in the newly built technical centre in Essen, we are able to carry out a wide range of different product tests.

Our test centre has been working for EUROVENT Certita Certification SAS (ECC) in Paris for more than 20 years. On behalf of this European certification organisation, we test the performance data of air conditioning technology devices. ECC relies on the technical expertise and decades of experience of the TÜV NORD test centre.