ISO 50001: Certified energy management system

There are many good reasons to pay attention to your company's energy efficiency. From a global perspective, it helps with the urgently needed reduction in greenhouse gas emissions. But a certified energy management system in accordance with DIN EN ISO 50001 also has advantages in terms of your company's profitability.

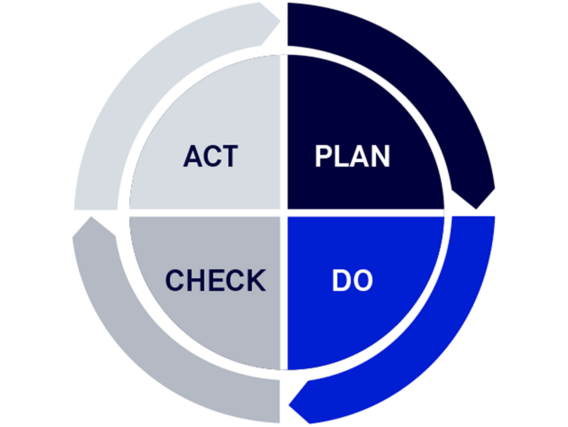

This is because a certified energy management system in accordance with ISO 50001 supports you in the continuous improvement of your energy-related performance, i.e. in the improvement of energy efficiency, energy use and energy consumption.

The energy management system also supports you in increasing your competitiveness and reducing energy costs. It also enhances your public image.