ISO 9001 Certification

An effective quality management system is essential in order to bundle the complex requirements of your company and lead it to success. It is important to react flexibly and quickly to changes and requests from customers and markets.

More than one million companies of all sizes and from a wide range of industries worldwide therefore rely on ISO 9001 certification for the quality assurance of their organisation. And for good reason: by applying the standard, they optimise their processes and at the same time ensure the satisfaction of their customers - and their competitive success.

You too can create the basis for efficient quality management with ISO 9001 certification. TÜV NORD is at your side as a certification partner with great expertise.

A quality management system in accordance with ISO 9001 is the ideal basis for companies of all sizes, both nationally and internationally, to demonstrate their expertise and performance. A key advantage is that the standard can be implemented across all sectors - both for production companies and service providers.

Process improvement - and thus improved economic efficiency

Companies often have other management systems in addition to quality management, such as environmental, energy and occupational health and safety management. The "High Level Structure" (HLS) - the standardised numbering and designation of the standard chapters as well as the use of standardised definitions and reference texts - makes it much easier to combine different management systems into an integrated management system (IMS).

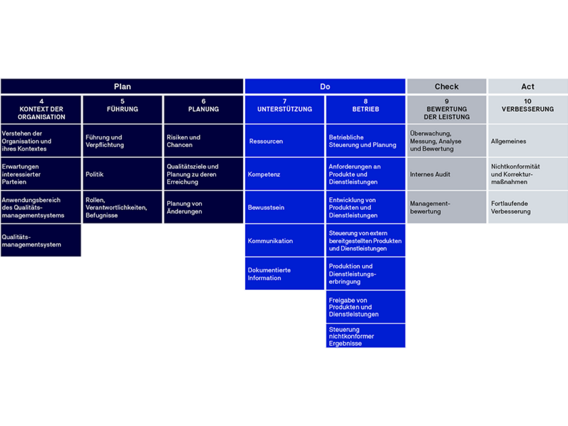

ISO 9001 certification specifies requirements for your quality management along the entire value chain .

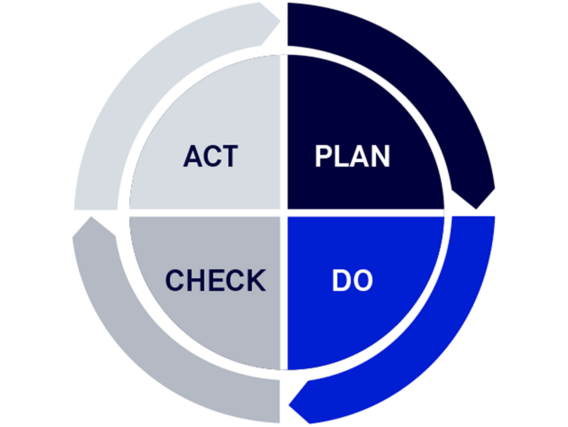

It is based on the Plan-Do-Check-Act model , which is divided into four phases. The aim is to continuously improve the individual processes as well as the overall system. As the name suggests, this means: plan the processes - carry them out - check them - and act.

As a management tool, the constantly repeating PDCA cycle is the driving force behind a continuous improvement process - both for individual company processes and for the overall system, including its products and services.

The approach prevents stagnation and ensures that companies are constantly adapting to changing situations. Those who decide in favour of the management system are thus embarking on a path of continuous development.

An integrated management system (IMS) combines a company's various management systems, such as quality, environmental, energy and occupational health and safety management, into a standardised structure. This promotes a standardised way of working, increases efficiency and transparency and offers numerous advantages:

Greater employee motivation: Transparency and clear objectives promote acceptance and identification.

An IMS improves efficiency, reduces costs, increases transparency and collaboration, and facilitates the fulfilment of legal requirements. The prerequisite for success is careful planning and implementation, with the High Level Structure (HLS) serving as a central basis to facilitate the integration of the various standards.

A quality management system in accordance with ISO 9001 is the ideal basis for companies of all sizes, both nationally and internationally, to demonstrate their expertise and performance. A key advantage is that the standard can be implemented across all sectors - both for production companies and service providers.

Companies often have several management systems. In addition to quality management, they include environmental, energy and occupational health and safety management. Thanks to its "High Level Structure" (HLS), ISO 9001 can be combined with other certifications to form an integrated management system.

Internal workflows, competences and responsibilities within the company are taken into account, as is the regulation of processes in cooperation with customers and business partners. This ensures global comparability and compatibility with other management systems.

ISO 9001 has been fundamentally revised in order to do justice to the increasing complexity of the markets and their environment. The focus of the 2015 revision is on process results and their effectiveness, no longer on documentation. Furthermore, the revision of ISO 9001 gives organisations more flexibility with regard to the implementation of their management system. For example, the standard adapts to today's business realities by also allowing documentation to be computer or web-based.