20 February 2019

Even the mighty Industrial Revolution needed common-or-garden water - specifically in the form of steam, which was used to drive the pistons of engines, pumps and locomotives. But lurking behind the new technological possibilities were some untold and unknown dangers. In our brief history of the steam engine, we relate how steam power was discovered, the risks that came with it, and how the steam boiler inspection associations, or DÜVs, set about protecting people from the technology.

In the beginning, as we all know, there was fire. Our ancestors used it to drive off wild animals, convert raw clay into pots, turn indigestible roots into nutritious food and transform hostile places into homes. And mankind has never since ceased in its development of new ways of turning the elements to our advantage: With wind power, it became possible to mill grain into flour and to sail across the oceans to unknown shores. Water power was used in turn to mill grain or saw wood. But the wind doesn’t blow everywhere, and ships and windmills lie idle whenever it dies away. The more dependable water power isn’t always on hand where you need it to drive water wheels, pumps, millstones or saws. It took the invention of the steam engine to guarantee supplies of drive energy at any location on earth – energy so powerful that not even workhorses could compete with it. James Watt is often celebrated as the father of this technology. However, the Scottish inventor was by no means the first person to investigate it.

Hero of Alexandria and the Aeolipile

The fact that steam could cause a pot lid to rattle and lift up had been investigated by a scholar of antiquity - namely, Hero of Alexandria – as early as the first century of the common era. In his “Pneumatica”, the Greek engineer and mathematician described machines which could be used to turn heat energy into kinetic energy: The lower part of his experimental design consisted of an air-tight water container which could be heated over an open flame. Above it was a rotating hollow sphere, which was connected to the vessel by two mounting brackets. When the water came to the boil, the steam would flow through one of the brackets into the sphere and out again through the two jets. This would generate torque which would cause the sphere to rotate. Hero’s Aeolipile is regarded as the first documented heat engine in history – and it would remain the only one of its kind for many centuries. It would take a further 1,500 years for the power of steam to be rediscovered.

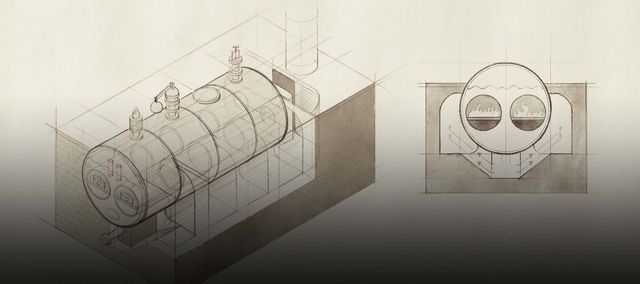

© TÜV NORDA steam boiler in Magdeburg around 1880.

From Denis Papin to James Watt

In 1690, Frenchman Denis Papin presented the first prototype of a steam engine, which worked using pistons and cylinders. This was followed in 1698 by a steam-powered device invented by British engineer Thomas Savery with the purpose of pumping groundwater out of mines. Although the device was not sufficiently practical to be commercially viable, the principle behind it was thoroughly sophisticated. Engineer Thomas Newcomen perfected the process in 1712 and developed the atmospheric steam engine. Although this was a great deal more efficient than Savery’s machine, it still required a lot of energy because the pistons and cylinders needed to be heated up and cooled down for every single work cycle. A problem that was resolved by James Watt with his double-acting steam engine, which he patented in 1769. It was “double-acting” because the cylinder was filled with steam alternately from both sides. As a result, the machine achieved an efficiency of almost three percent. This doesn’t sound like much from today's perspective, but it represented a six-fold increase in output from Thomas Newcomen’s steam engine. And because a new technology needs a unit of measurement that everyone can relate to, James Watt placed the power of a horse in mathematical relation to the work carried out by it and came up with the idea of horsepower - or HP for short.

Technology with explosive force

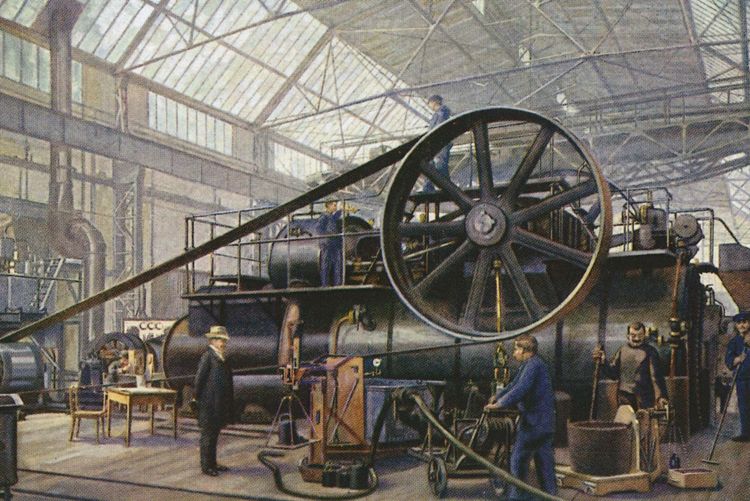

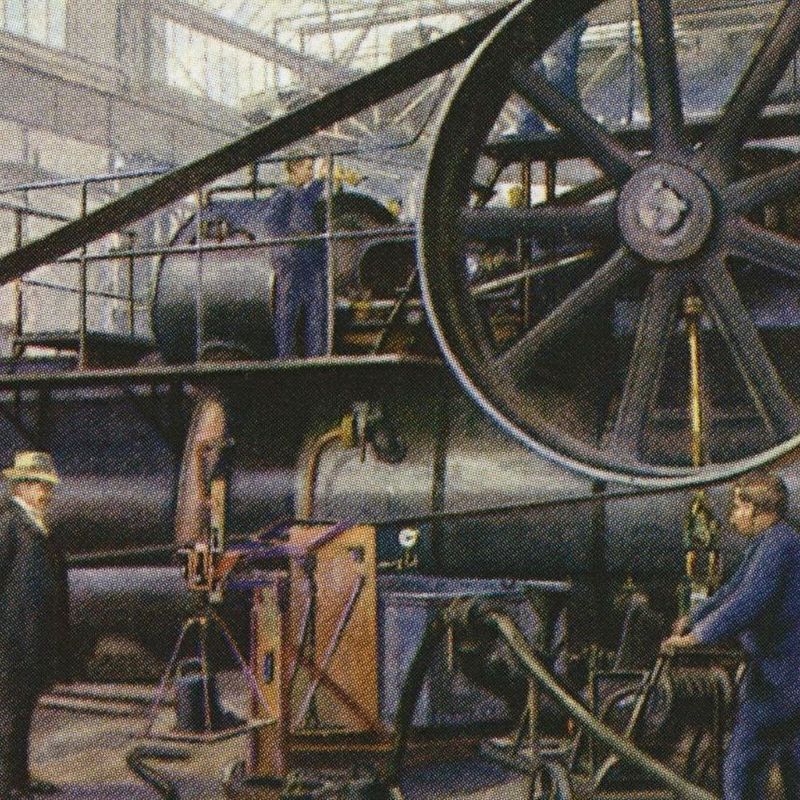

The development of the steam engine inspired researchers and engineers to come up with a continuous stream of new applications for this revolutionary machine. It found its way into weaving and spinning workshops, got the industrial-scale production of coal, iron and steel firing on all cylinders and finally opened up new ways of getting people and goods from A to B, both on land and at sea: In 1807, on the Hudson River, Robert Fulton announced the dawning of the steamship age; the first public railway line was opened in England in 1825. In the German statelets, too, industrialisation rapidly gained momentum: Whereas, in 1849, a mere 651 steam engines, with a total power output of 18,775 HP, were in operation in the Rhineland and Westphalia, only 25 years later that figure had ballooned to 11,706 machines with a combined output of 379,091 HP. The spread of the new technology was explosive – unfortunately, in more than one sense of the word.

© TÜV NORDThe explosion of a steam boiler often caused serious accidents. Here, in Chemnitz, it led to a total destruction of the boiler house.

On 27 January 1855, the city of Hanover witnessed a catastrophic event. A steam boiler exploded in a local wagon factory, killing seven workers instantly and badly injuring many more. Devastating accidents like this became commonplace. According to early statistics, in the German Empire alone in the years 1877 to 1890, there were more than 200 steam boiler explosions, which left nearly 200 people dead and over 100 seriously injured. Alongside inadequate maintenance, design flaws and excessive steam pressure, overheating through lack of water was one of the most common causes of boiler explosions. This was because overheating the boiler walls could cause them to crack, leading to the abrupt vaporisation of the water in the boiler – and the sudden release of pressure would result in a huge explosion. Installing boilers in factories would often translate this risk into devastating accidents. Gears with belts were used to harness the power of the machines for as many work stations as possible, and these belts could not be over a certain length. Short pipes were deployed to minimise steam and heat loss. Which is why steam boilers and engines were installed close to the workplaces – right in the midst of the workforce.

Safety through voluntary obligation

Alarmed by the increasing number of boiler explosions, European states undertook to stem the tide. Prussia first introduced mandatory regulatory controls in 1856, but these proved largely inadequate to the task. Although the local police authorities were initially responsible for the monitoring of steam boilers, this task was later taken over by official surveyors or local master builders – like the police, however, these latter did not in most cases have the experience or specialist knowledge required to deal properly with the installations.

Hamburg’s steam boiler operators and shipping companies came to the inescapable conclusion that experts needed to be called on to monitor the safety of their boilers. It was for this reason that they founded the “Norddeutscher Verein zur Überwachung von Dampfkesseln in Hamburg” (“The North German Association for the Monitoring of Steam Boilers in Hamburg”) on 15 June 1869.This was Germany’s second steam boiler inspection association, which became known by its German acronym DÜV, and, like the association which had been founded in Mannheim, it took its cue from the English model. English entrepreneurs had founded the Manchester Steam Users Association - the first technical inspection association in the world - as early as 1855. As a public self-governing body, this association took on the task of inspecting its members’ boilers and reduced the number of boiler accidents to a level ten times lower than that achieved by the state-appointed inspectors in Prussia.

© TÜV NORDNo controls without measuring devices: a piece from the archives of TÜV NORD in Magdeburg.

The private steam boiler monitors in Germany, too, achieved considerable success in a short time. In his inspection district, Magdeburg-based DÜV engineer Rudolf Weinlig succeeded in reducing the incidences of external boiler damage from 60 to 20 percent between 1871 and 1873, also slashing the dangers posed by the internal workings of the boilers, which had until then hardly attracted any attention, from 30 to 16 percent.

An audience with the “Iron Chancellor”

As technical director of the largest Prussian DÜV, he was granted an appointment with Prussian Prime Minister Otto von Bismarck in 1884. Weinlig convinced the Iron Chancellor that it was a good idea for the DÜV not only to inspect the boilers but also to grant permits for their operation and to officially test and pass them after commissioning.The state also effectively recognised the “principles created by the associations for the testing of materials for the construction of steam boilers” (Würzburg standards) and the “proposals for the calculation of the panel thickness for new boilers” (Hamburg standards) as official rules.

In the Reich industrial regulation of 1 April 1900, the DÜV was then granted legal authority for the monitoring of steam boilers. As a result, they were not only responsible for the safety of their members but were also given the power to inspect the boilers of non-members.28 associations with 273 engineers were now monitoring 89,000 steam boilers throughout the German Empire They also came up with ideas and made proposals to increase the economic efficiency of the machines. To this end, the Magdeburg DÜV set up its own laboratory in 1881, in which, for example, the calorific values of different types of coal could be calculated.

© TÜV NORDCompiled knowledge dating from 1911.

Germany’s quest for the boilermen’s boilerman

But even the best technical safety measures are of little use when confronted with the human risk factor. Many accidents were indeed a consequence of operator error. This should hardly have come as a surprise: after all, many steam boilers heaters were operated by unskilled and low-paid workers. They had no idea exactly how the boiler which they spent their days shovelling coal into actually worked. Out of sheer ignorance, they often blocked safety valves, bunged up the warning whistles or over- or underfilled the boilers with water.

The weapon wielded by the DÜV in the campaign against accidents was training. The DÜV in Magdeburg hired an expert boilerman as a tutor, whose job was to train local boilermen in the theory and practice of steam boilers, as early as 1874. But these offers initially met with deaf ears on the part of the factory owners. Training boilermen would take them out of the factory, cost extra money and contribute little – this was, at least, the rather short-sighted assessment of many entrepreneurs.

© TÜV NORDSmall stamp with a huge effect for the „Magdeburger Verein für Dampfkesselbetrieb“.

It took a competition between boilermen in 1885 to finally turn things around. Not only were the boilermen who had been trained in courses fully conversant with all the safety requirements, but they also needed only half as much coal as their untrained colleagues to generate the same amount of steam. This savings potential immediately led many entrepreneurs to see the light. Courses for boilermen were suddenly all the rage – not only in Magdeburg, but also in Hanover, where the DÜV’s trainer of boilermen had until then been operating very much away from the limelight.

This was a development from which the boilermen themselves also profited. From low-paid unskilled and auxiliary employees, they now became sought-after specialists who could command much better salaries. The DÜV boiler specialists in turn evolved into experts in the safety of those new and more powerful technologies - from electricity to the internal combustion engine - that would go on to end the age of steam. Their remit now included inspections of the first low-powered automobiles to start trundling down the country’s roads. This was an obvious new departure: after all, the first cars were still powered by steam engines. The word “chauffeur”, the French term for boilerman, reminds us to this day of these oft-forgotten early days.