Industrial 3D printing

Additive manufacturing

We test, certify and support additive manufacturing along the entire production chain – throughout Europe and in accordance with standards.

Industrial 3D printing

We test, certify and support additive manufacturing along the entire production chain – throughout Europe and in accordance with standards.

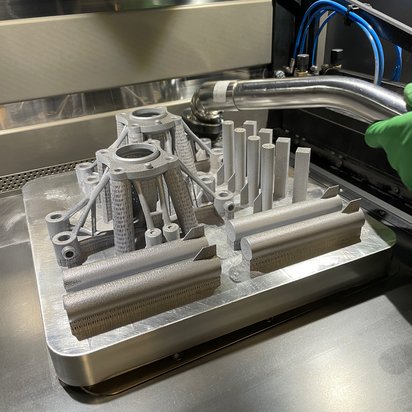

Additive manufacturing, or 3D printing, is a new manufacturing technology. 3D printing enables the tool-free production of highly complex components made from metals or plastics. The workpiece is built up layer by layer with high precision.

Industrial 3D printing is completely digital and uses practically all Industry 4.0 aspects: Based on digital CAD design and optimization, production is carried out by melting metal powder layer by layer. The component properties and the component material are created from the properties of the metal powder and are dependent on the digital construction instructions used for the production system.

Sensors constantly monitor the process during production. The production result is validated using the digital twin and accompanying printed samples. The final quality control uses highly developed non-destructive methods such as computer tomography. The entire design and manufacturing process is digitally traceable.

Additive manufacturing enables the production of components that were not possible with conventional manufacturing processes. 3D printing enables the integration of individual component optimizations and new functions in a previously unknown way.

You can find more information in the expert interview with Jens Groffmann at #explore: Where does 3D printing stand today?

The DIN EN ISO/ASTM 52920 standard raises the additive manufacturing of components to an industrial level, especially for safety-relevant components. This standard provides a comprehensive framework for the manufacture of components and ensures that these innovative manufacturing techniques for your components meet the high safety and performance requirements of the respective industry.

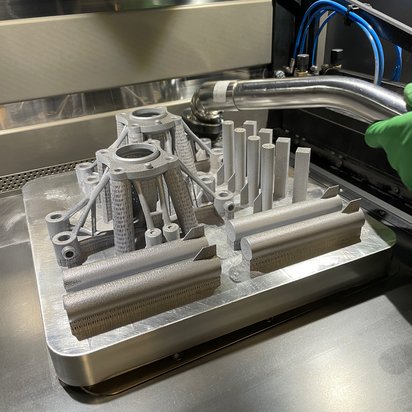

TÜV NORD and Additive Marking support industrial 3D printing with customised services in the area of Testing, Inspection & Certification, in particular with production samples to determine the material properties.

We provide you with individually configured STL files of the necessary production samples for 3D printing for download via our webshop. Clearly traceable production samples are provided for customised testing services, which are inspected and tested in the accredited TÜV NORD laboratories.

This enables our customers to quickly, easily and reliably make reliable statements about the mechanical and technological properties of their construction jobs. The test specimen files are configured ready for printing and are simply added to the production run to be tested. After production, the accompanying samples are sent to TÜV NORD for testing free of charge by a logistics service provider. The TÜV NORD laboratories determine the material characteristics in accordance with internationally recognised standards and provide the results in digital form.

The iam-approved.com web store is primarily aimed at small and medium-sized 3D printing service providers who are faced with new challenges, such as proving material properties achieved in production to their clients and customers.

The decisive advantage lies in the automated and clear labeling of the samples at the moment they are created. This completely eliminates the usual time-consuming and error-prone manual labeling effort, both on the customer side and later in the test laboratory. This special form of marking is a unique selling point and is only offered by TÜV NORD and Additive Marking.

The range of tests for additively manufactured accompanying samples includes all standard test procedures, such as notched bar impact tests according to DIN EN ISO 148-1 and tensile tests according to DIN EN ISO 6892-1. The joint TÜV NORD and Additive Marking web store will initially launch with a small selection of tests, which will be successively expanded to include further services for additive manufacturing.

The serialized and clearly traceable production samples simplify and speed up processes enormously for 3D printing service providers. You get an all-inclusive package, from the provision of the right test specimens to the elimination of manual production documentation and the digital transmission of test results.

TÜV NORD and Additive Marking support industrial 3D printing with customised services in the area of Testing, Inspection & Certification, in particular with production samples to determine the material properties.

Certified management systems are the key to market access and the prerequisite for deliveries in regulated areas such as aerospace, pressure equipment manufacturing or medical technology. TÜV NORD offers you both basic certification of your management systems in accordance with DIN EN ISO 9001: 2015 as well as special certifications, for example for the automotive industry.

Take advantage of our expertise in the fast and reliable determination of the mechanical and technological properties achieved in production. Our accredited test laboratories carry out all tests for you quickly and efficiently in accordance with standards.

Our range of tests for additive-manufactured accompanying samples includes all standard test procedures, such as

Notched bar impact test in accordance with DIN EN ISO 148-1

Tensile test in accordance with DIN EN ISO 6892-1

We are happy to coordinate the type and scope of the accompanying samples required for additive manufacturing in advance.

If required, we can of course offer you further materials testing of your additively manufactured components based on your specific questions.

In addition to the comprehensive analysis of your production samples, we also offer proven logistics solutions for sample transport as well as meaningful documentation of the test results.

You can find more information on materials testing at the following link.

To our webshop 3D printing - tests and certification | TÜV NORD

In addition to our standard tests for additive manufacturing, we also offer damage analyses or tests with extended temperature levels, for example.

DIN EN ISO / ASTM 52907 - Test programme

Material samples incl. storage serve as proof of the powder actually used in production

The properties of the starting material, together with the process parameters used in the additive manufacturing system, determine the material properties of the component you produce.

But: What properties does your starting material have? Do the properties of your metallic powders meet your own requirements? Are your customers' specifications being met?

Play it safe and have the properties of your starting material independently determined by TÜV NORD analyses. We analyse your material samples quickly and reliably in accredited laboratories on the basis of a TÜV NORD test programme. For example, we provide you with valuable information for the individual optimisation of your machine settings through reliable information on the grain size distribution of your starting material. Of course, we also test the primary material according to other common international test specifications.

TÜV NORD supports you with a wide range of component testing options, both in the non-destructive area and destructive tests (see mechanical-technological tests) for special applications. Our laboratories offer the entire range of non-destructive testing methods. To identify pores, cracks and similar discontinuities, we use the X-ray technology best suited to your application. In the high-end sector, computer tomography offers excellent possibilities for analysing components and enables detailed inspection of the internal structures of your additively manufactured component.

The DIN EN ISO/ASTM 52920 standard raises the additive manufacturing of components to an industrial level, especially for safety-relevant components. This standard provides a comprehensive framework for the manufacture of components and ensures that these innovative manufacturing techniques for your components meet the high safety and performance requirements of the respective industry.

Together with industry partners, TÜV NORD is currently investigating new ways of qualifying and certifying the additive process chain in pilot projects. Our focus is on the independent testing, confirmation and prospective certification of stable series production in relation to

We would be happy to present the details to you in personal discussions.

Further information TÜV NORD Systems