Hydrogen as energy carrier

Hydrogen is considered a central pillar of the energy transition and an important driver of decarbonization. The energy carrier, ideally in its green form, has the potential for another revolution in the energy sector. Hydrogen will play an important role in the energy mix, bridging the gap from generation to storage and distribution to seamless supply and driving the necessary sector coupling. So whether as a storage medium for energy, or in electricity and heat supply, or even as a fuel for clean mobility - hydrogen has great potential as an energy carrier. Moreover, in the field of reverse power generation, hydrogen is a "no-regret" application. This means that the use of H2 makes economic, ecological and social sense in many applications, with or without the consequences of climate change. The economic aspect in particular has recently gained in importance due to the rising costs of fossil fuels.

Hydrogen suitability of combined cycle gas turbine (CCGT) power plants

The European Union has committed itself to being climate neutral by 2050 at the latest. The Federal Government envisages this for Germany as early as 2045. For the corresponding implementation, the energy supply must also be reconsidered. A successful energy transition requires a combination of security of supply, affordability and environmental compatibility with innovative and sustainable climate protection. Here, hydrogen can, must and will replace the predominant natural gas in many places. With regard to the above-mentioned time horizon, this also means that power plants built in the near future must be capable of climate-neutral operation, i.e. they must be suitable for hydrogen, for example. If these are fired with H2 or a mixture of H2 and natural gas, new questions will arise, especially with regard to safety precautions and the technical conditions. TÜV NORD uses a specially developed H2-ready evaluation scheme to evaluate the hydrogen suitability of CCGT plants. The starting point is the concept phase of the construction or expansion of a CCGT power plant.

If you are interested in this topic, please contact our experts at TÜV NORD. We will be happy to submit a non-binding offer for an evaluation of your H2-readiness status on the way to a climate-neutral CCGT plant.

H2-readiness of combined cycle gas turbine power plants

Combined-cycle gas turbine (CCGT) power plants will make an important contribution to the upcoming transformation and to meeting climate targets. In addition to high efficiency and the relatively easy conversion to hydrogen, they have another advantage: energy supplies with a short start-up time, as with combined cycle gas turbines, make it possible to fill supply gaps promptly. This is because the increasing share of renewable energies means more and more power fluctuations due to the non-constant availability of light and wind. In a climate-neutral energy supply, H2-fuelled CCGT power plants can therefore be used for reverse power generation on a larger scale. For this, newly built plants must be H2-ready, which, according to the underlying scheme, means that they can be operated with 100% hydrogen.

With TÜV NORD's evaluation scheme for new and existing combined cycle gas turbine power plants, plants and systems can be evaluated on a project- and customer-specific basis in three H2 readiness levels from the early planning phase. No matter whether on behalf of operators, manufacturers, insurers or OEMs. In the present procedure, the consideration limits can be planned individually, are component-related and provide an independent orientation and evaluation aid for the future safety of the power plant concept. In addition, long-term planning with an average operating time of approx. 35 years protects the plant from unplanned downtimes and premature decommissioning. "H2-ready" in the plant construction of a CCGT power plant makes the operation competitive and future-proof on the way to climate neutrality.

TÜV NORD evaluation scheme for H2-readiness

But what is meant by H2-readiness in this evaluation scheme? In the TÜV NORD evaluation scheme, H2-ready to use (1) refers to suitability for use with hydrogen as the sole fuel in CCGT components or systems. In the actual combustion process, H2 replaces natural gas.

Due to other properties, there are changed technical requirements for components and systems, which are classified and addressed with the help of the evaluation scheme. The stage H2-ready to adjust (2) means that components have to be modified or replaced for operation with hydrogen. Here, conversion is basically feasible.

Unfit for H2 (3), on the other hand, is the rating if the exchange or modification of parts and components necessary for use with hydrogen is not possible. The classification can be made modularly for individual components or subsystems, up to the evaluation of an entire CCGT power plant. H2-readiness can thus be divided into 3 levels: Operation with H2 immediately possible (1), operation possible after retrofitting (2) and retrofitting impossible or not reasonable (3)

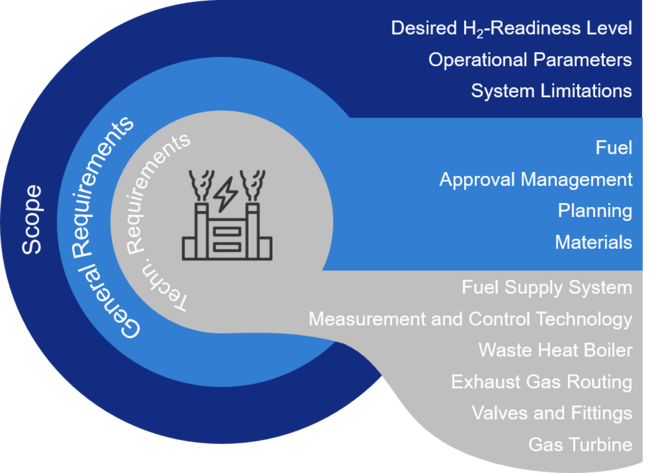

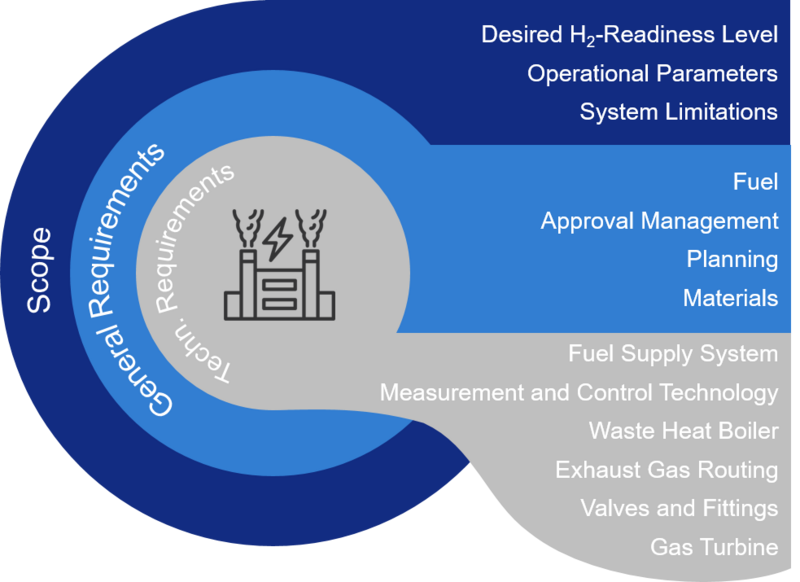

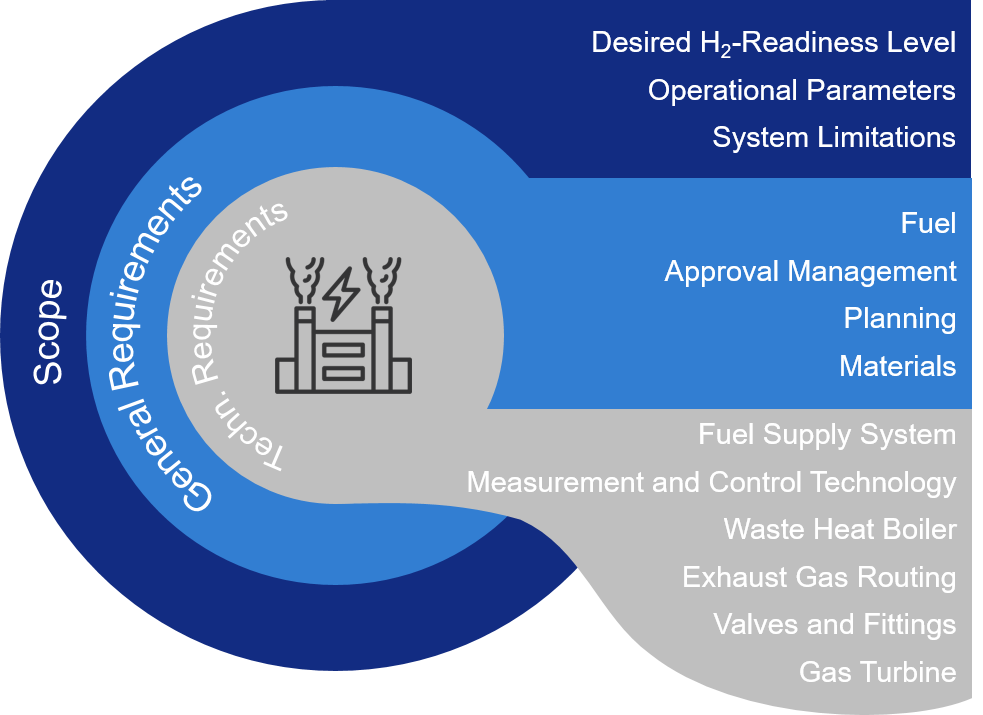

The evaluation scheme can be understood as the basis for the "roadmap" for the construction of a new CCGT power plant or the retrofitting of an existing one. It can be adapted to the actual needs of the customer. The evaluation scheme is divided into four steps, starting with the target definition with a requirements matrix, overarching requirements (e.g. fuel, permit management, planning, materials), technical requirements (e.g. fuel supply system, gas turbine, waste heat boiler, valves and fittings, measurement and control technology) and ending with the final evaluation. The evaluation is based on existing technical rules, norms and standards, where applicable and available.

The results at the end of the process allow the upcoming measures on the way to H2-readiness to be classified. For the customer, the results provide a number of advantages: The results represent neutral proof of the technical feasibility of the (sub)projects. They pave the way to climate-neutral operation of their plant on the basis of securing the future of the system. Moreover, the results serve as orientation in a dynamic environment of a rapidly and constantly changing energy landscape.