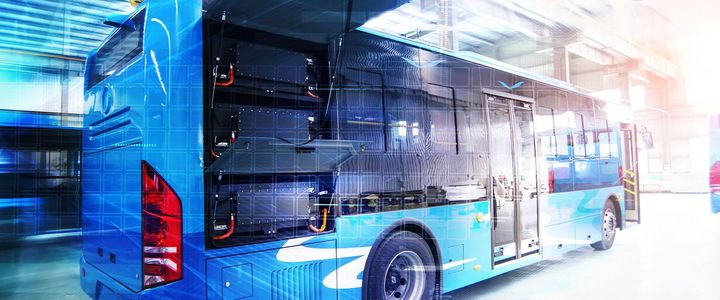

Highly individualized buses and non-automated production lead to challenges, especially with new technologies such as hydrogen-, or electric-powered buses, which require the highest level of accuracy.

TÜV NORD Mobilität has developed a web-based, data-driven solution that is used by its highly qualified bus experts to check and report vehicle quality during the production process or before delivery as a final check.

Sales of electric buses worldwide

The bus industry is booming and becoming increasingly international - both buyers and manufacturers must be able to rely on their respective contractual partners:

- On the customer side, there is a need to stay informed about bus quality - i.e. compliance with the specification, possible quality defects or functional failures - during production and before final acceptance.

- On the manufacturer's side, it is important to ensure and make visible that his/its own work complies with the required specification and is free of defects.

Accordingly, both sides benefit from a neutral authority that is present at the various production steps upon need.

Our TÜV NORD bus inspection team can do that:

- Auditing of the pre-runner vehicle (first bus from the series)

- Quality assurance during the entire manufacturing process

- Pre-delivery inspection (PDI) – final inspection

Your advantages when entrusting TÜV NORD Mobilität with bus inspection:

- You receive transparent information about vehicle condition at every production step

- The vehicle corresponds to the specifications ordered and the quality you expect

- You save recall costs and avoid damage to your reputation

- You reduce your expenses by saving audit work

- Your new bus lines can start on time

- You invest in the trustworthiness of your fleet and safety of your passengers

- In case of a warranty claim, you are reliable documentation available

These are the services of TÜV NORD Mobilität for you in bus testing

- Pre-delivery inspection (final quality check)

- Quality assurance during whole manufacturing process

- Pre-runner inspection (1st bus of the batch)

- End of warranty check

- Buy back inspection

- Vehicle functions control

- Compliance with the specification

- Departure check

- Compliance with norms and regulations

- Quality analysis of previous deliveries

- Suggestions for product improvements

- Sub-system control (infotainment, ticket machine, monitoring system)

- CNG or H2 system control

- Fire accident investigation (additional pdf attached)

- Battery condition assessment (SOC, SOH, degradation)

How do you benefit from the TÜV NORD bus inspection:

- Digital fault documentation and reporting in real time

- Sustainable quality control by the recognized testing organization TÜV NORD Mobilität

- Sustainable fault documentation over the entire life span of the bus, relevant for long-term warranties (corrosion, battery pack, fire extinguishing system, gas system etc.)

- Enormous cost savings for the transport operator, as it is no longer necessary to delegate inspection personnel for the initial acceptance and the re-acceptance after defect has been rectified

- Maximum possible safety, especially when using vehicles with new drive technologies such as electric buses and hydrogen-powered buses

Sorry, this video can not be played because of your privacy setting.

You can change your settings here anytime.

Do you have any questions about bus testing - please contact us