Additive manufacturing and 3D printing technology

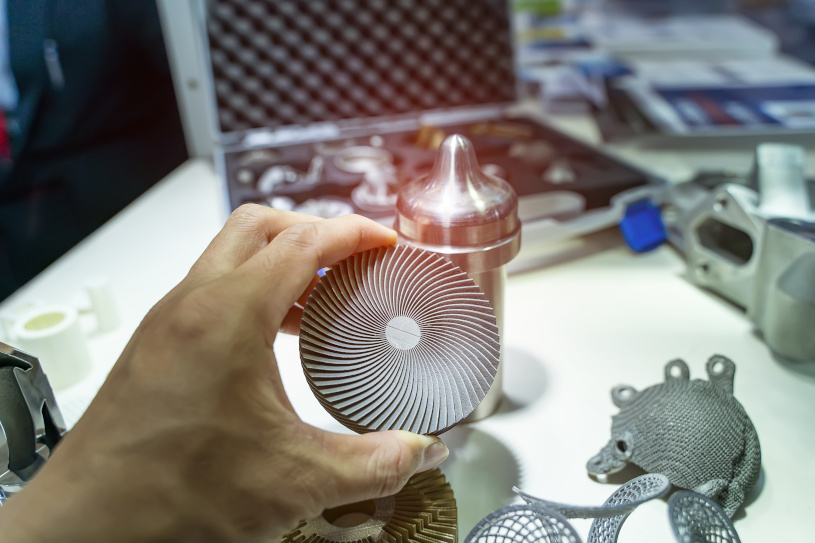

Additive manufacturing or “3D printing” is a new manufacturing technology. 3D printing allows for the toolless production of high-complexity components in metal or plastic. The workpiece is built up layer by layer to a high level of accuracy.

Industrial 3D printing is fully digital and makes use of practically all aspects of Industry 4.0:

After digital CAD construction and optimisation, manufacture takes place through the application of layers of liquid metal powder. The properties of the component and its material are defined by the characteristics of this metal powder and depend on the digital instructions used by the production plant.

During manufacture, sensors constantly monitor this process. The result is validated using simultaneous digital twin and test samples. The final quality control makes use of high-tech non-destructive processes such as computer tomography. The entire construction and manufacturing process can be digitally tracked.

Additive manufacturing allows the production of components that would not be possible through conventional processes. 3D printing allows the integration of individual component improvements and new functionalities to an unprecedented degree.

You can find further information in the expert interview with Jens Groffmann at #explore: Where is 3D printing at today?

Additive manufacturing can be used first and foremost in the following sectors:

- General mechanical engineering

- Process industry, e.g. flow-optimised valves or pumps

- Medical technology, e.g. individual prostheses

- Dental technology

- Vehicle technology, shipbuilding

- Aerospace engineering

Webshop iAM-approved as cooperation between TÜV NORD and Additive Marking

TÜV NORD and Additive Marking support industrial 3D printing with tailored services in the area of Testing, Inspection & Certification, in particular with production samples to determine material properties. Via our Webshop iAM APPROVED, we provide you with individually configured STL files of the respective required production samples for 3D printing for download. Unambiguously traceable production accompanying samples are provided for customized testing services, which are inspected and tested in the accredited TÜV NORD laboratories. This enables our customers to make reliable statements about the mechanical-technological properties of their construction jobs easily, reliably and quickly. The files of the test specimens are configured ready for printing and are simply added to the production run to be tested. After production, the accompanying samples are sent free of charge to TÜV NORD for testing using a logistics service provider. The TÜV NORD laboratories determine the material characteristics according to internationally recognized standards and provide the results in digital form.

FAQ about the webshop

The iam-approved.com web store is aimed primarily at small and medium-sized 3D printing service providers facing new challenges, such as proving material properties achieved in production to its clients and customers.

The decisive advantage lies in the automated and unambiguous labeling of the samples at the moment of their creation. This completely eliminates the otherwise time-consuming and error-prone manual marking effort, both on the customer side and later in the test laboratory. This special form of marking is a unique selling point and is only offered by TÜV NORD and Additive Marking.

The range of tests for additively manufactured accompanying samples includes all standard test procedures, such as notched bar impact tests according to DIN EN ISO 148-1 as well as tensile tests according to DIN EN ISO 6892-1. Initially, the joint TÜV NORD and Additive Marking web store will start with an initial small selection of tests, which will be successively expanded to include further services for additive manufacturing.

The serialized and uniquely traceable manufacturing test specimens result in enormous simplifications and acceleration of processes for 3D printing service providers. They get an all-inclusive package, from the provision of the right test specimens to the elimination of manual manufacturing documentation and the digital transmission of test results.

TÜV NORD offers the following services for additive manufacturing

Component-related tests

TÜV NORD supports you with a wide range of component testing possibilities for special applications, both destructive and non-destructive (see mechanical/technological tests). Our laboratory offers the full range of non-destructive testing processes. To detect porosities, cracks and similar discontinuities, we will choose the right X-ray technologies for your application. In the high-end range, computer tomography offers excellent opportunities for component analysis and allows a detailed inspection of the interior structures of your 3D-printed part.

Personnel certification

TÜV NORD certifies between 20,000 and 25,000 personnel per year in the field of joining technology. Get your personnel qualified in the field of additive manufacture and quality management!

Operator examinations can be based, for example, on DIN 35225 “Welding for aerospace applications – Qualification testing of operators for powder bed based laser beam machines for additive manufacturing” or on DIN EN ISO 14732 “Welding personnel – Qualification testing of welding operators and weld setters for mechanized and automatic welding of metallic materials”.

Certified management systems

Certified management systems are the key to market entry and the prerequisite for gaining access to regulated sectors such as aerospace engineering, pressure vessel construction or med-tech. TÜV NORD offers both basic certification of your management systems to DIN EN ISO 9001: 2015 and special certification, for example, for the automotive industry.

Mechanical/technological tests

Make use of our expertise in rapidly and reliably determining the mechanical and technological properties achieved in manufacture. Our accredited test labs carry out all investigations swiftly, efficiently and to the applicable standards.

Our range of trials for 3D-printed test samples covers all the standard processes, such as:

- Charpy pendulum impact test to DIN EN ISO 148-1

- Tensile test to DIN EN ISO 6892-1

We will be happy to agree in advance on the number and type of test samples to be produced on the side during additive manufacture.

Naturally, we can also offer materials science investigations for your 3D-printed parts, based on the questions you would like answered.

Alongside the comprehensive analysis of your production samples, we also offer tried-and-tested logistics solutions for sample transportation and informative documentation of the test results.

Primary material tests

The characteristics of your primary material, alongside the process parameters used in your 3D printer, determine the material properties of the component you manufacture.

But what are the properties of your primary material? Does your metallic powder come up to your requirements? Have your customers’ specifications been met?

Be on the safe side and have TÜV NORD independently analyse the properties of your starting material. Our accredited laboratories will rapidly and reliably analyse your material samples on the basis of a TÜV NORD testing programme. For example, our reliable grain size distribution analyses can provide you with valuable information to help optimise your machine settings. Naturally, we will also inspect the primary material against other current international test specifications.

TÜV NORD testing and quality assurance for additive manufacturing (video)

TÜV NORD outlook: validating the additive process chain

Together with industrial partners, TÜV NORD is currently carrying out pilot projects to define new methods of qualification and certification in the additive process chain. Our focus is on the independent inspection, approval and perspectival certification of stable serial production with relation to

- the product,

- the process and

- the manufacturer.

We will be happy to provide details in a personal meeting.